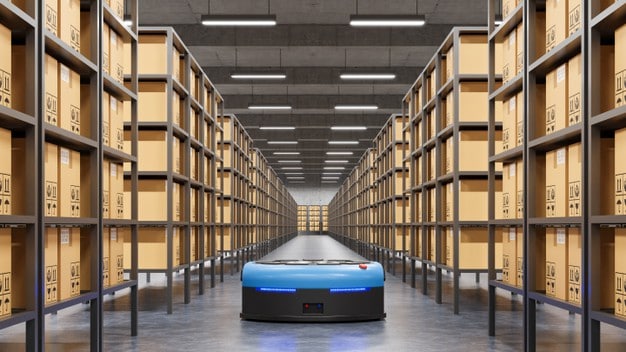

Automation is the future of forklifts, and the technology has reached a new level with Automated Guided Vehicles (AGVs). The latest in AGV technology is changing the way warehouses and distribution centers function, and Ring Power has access to it. The benefits of AGVs are numerous and can greatly increase efficiency, productivity and safety.

AGVs are robotic vehicles that can navigate independently across a variety of surfaces, using sensors to locate and avoid obstacles. They can move materials and products around a facility with precision and speed, without the need for human operators. AGVs make use of advanced mapping and guidance technologies, including laser guidance and radio frequency identification (RFID) tagging, to navigate and position goods accurately.

One of the benefits of using AGVs is increased efficiency, due to their ability to transport products and materials quickly and accurately. Traditional forklifts require a trained operator to maneuver them, and manual errors and delays can occur. With AGVs, there is no waiting for an operator, no delays due to manual mistakes, and a faster flow of products and goods through the facility.

AGVs also help to reduce the risk of accidents and worker injuries. Manual forklift operators are at risk of injury due to the physical demands of operating a forklift, and accidents can occur due to human error. With AGVs, there is no human operator involved, and so the risk of accidents or injury is significantly reduced. This means that employees can work more safely and efficiently, with less downtime due to injuries.

Another significant advantage of using AGVs is the cost savings they can provide. AGVs can operate 24/7, without needing breaks or shift changes. This means that companies can reduce their labor costs, while increasing efficiency and productivity. AGVs are also low maintenance, as they require less maintenance than traditional forklifts.

At CHQ Tools Co., Ltd., we recognize the benefits of AGVs and the importance of automation in warehouse and distribution centers. We are a professional manufacturer of woodworking tools and precision screwdriver kits, and we have our own team of professional engineers. We understand the challenges of operating a warehouse and the benefits that automation can provide.

In conclusion, AGVs are changing the future of forklifts and are revolutionizing the way warehouses and distribution centers operate. They are efficient, safe and cost-effective. CHQ Tools Co., Ltd. is committed to providing high-quality tools and supporting automation and innovation. We strive to help our customers realize the potential of AGVs and to provide them with the tools they need to succeed in the rapidly-evolving logistics industry.