Planer Machines: Boosting Efficiency and Precision in Metalworking

In the manufacturing industry, metalworking is an essential process that involves shaping, cutting, and assembling metal components to create finished products. To achieve precision and accuracy in metalworking, various machine tools are utilized, one of which is the planer machine.

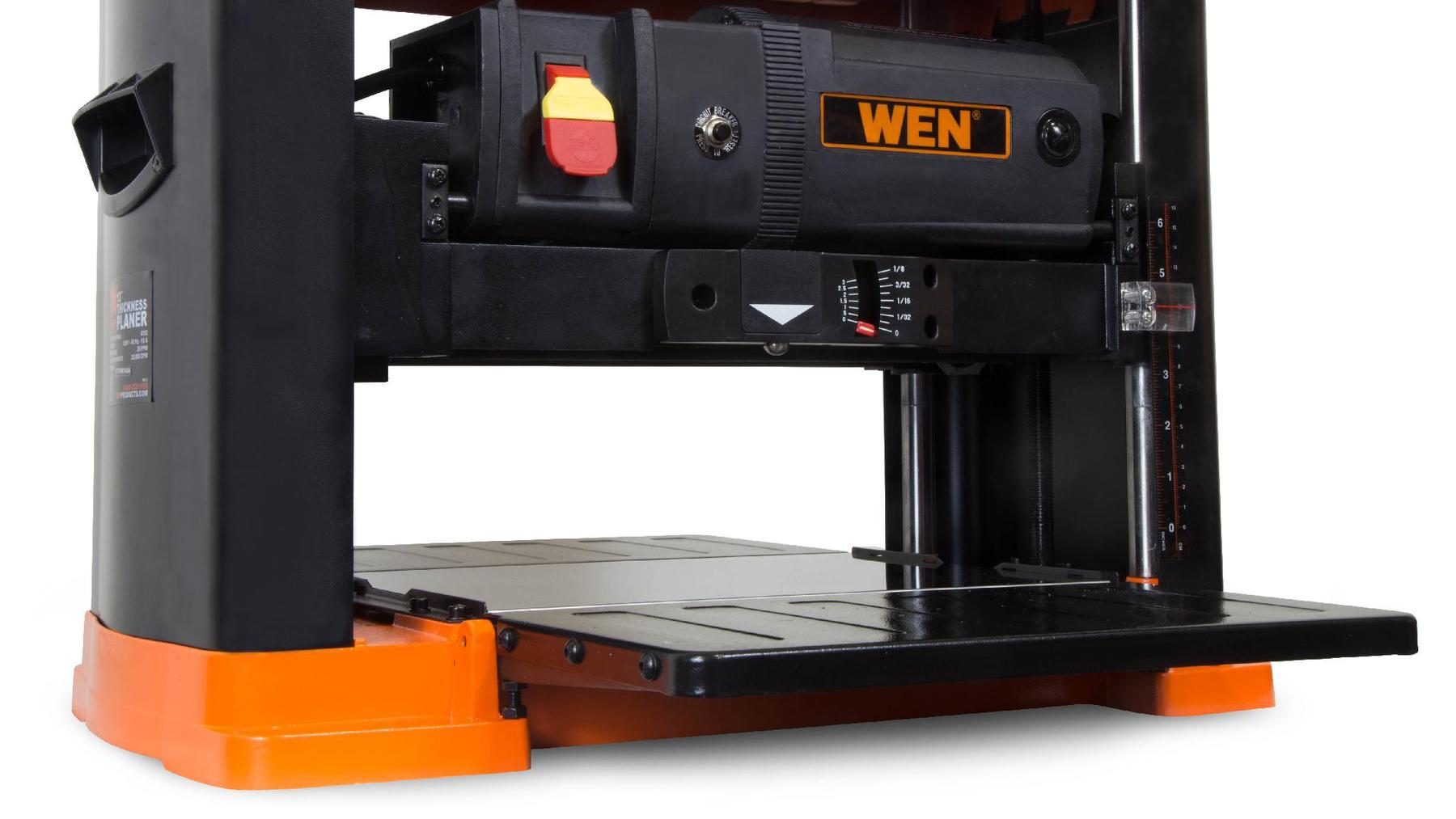

The planer machine is a metal-cutting tool that utilizes a single-point cutting tool to create flat surfaces on a workpiece. This process is done by attaching the workpiece to a horizontal table that moves back and forth while the cutting tool is held by a device mounted on a crossrail.

With its ability to remove excess material and create smooth and flat surfaces, the planer machine is widely used in various industries, including automotive, aviation, construction, and manufacturing. Its use is not limited to metalworking, as it can also be used in woodworking and other materials.

CHQ TOOLS CO.,LTD, a professional manufacturer of woodworking tools and precision screwdriver kit, has been producing quality planer machines since its establishment in 2016. With its team of professional engineers and dedication to innovation, CHQ TOOLS has become a trusted name in the manufacturing industry, providing efficient and accurate machines to boost productivity and quality of work.

Advantages of Using a Planer Machine

1. Precision and accuracy.

A planer machine utilizes a single-point cutting tool to create flat surfaces, ensuring precision and accuracy in every cut. With its ability to create smooth surfaces, it can also reduce the need for manual finishing, saving time and resources without sacrificing quality.

2. Efficiency.

With its ability to remove excess material quickly, a planer machine can significantly reduce the time it takes to cut and shape a workpiece, increasing productivity and output. This advantage is especially beneficial for high-volume manufacturing processes.

3. Versatility.

A planer machine can be used on various materials, including metal, wood, plastic, and more. This versatility makes it a valuable addition to any manufacturing process, allowing for flexibility in product design and production.

4. Cost-effectiveness.

Investing in a high-quality planer machine can be a cost-effective solution for manufacturing processes, as it can reduce the need for manual labor and increase productivity. With the ability to create precise and accurate cuts, it can also minimize waste and maximize material usage, leading to cost savings in the long run.

Conclusion

With its precision, efficiency, versatility, and cost-effectiveness, a planer machine is an indispensable tool in the manufacturing industry. As a trusted manufacturer of quality woodworking tools and precision screwdriver kit, CHQ TOOLS CO.,LTD is committed to providing reliable planer machines to boost productivity and quality of work. Whether for metalworking, woodworking, or other materials, a planer machine is an investment that can yield significant returns for any manufacturing process, and CHQ TOOLS CO.,LTD has the expertise and dedication to provide the best machines for the job.